Air Conveyor Systems / Pneumatic Conveyor Systems

Bevco’s Air Conveyor Systems / Pneumatic Conveyor Systems is ideal for moving lightweight PET bottles which can tip over on standard conveyors. The Air / Pneumatic Conveyor System runs at high speed (up to 1200 bpm) which allows the bottles to catch up when a gap is created between bottles in the production line due to equipment stoppage or pallet changeover.

General Operations

Bottles are picked up and controlled by standard neck rings on the bottles. They are then transported in a single file using air pressure in a plenum. Since the bottles are captured at the neck, they will not fall down or tip.

The pressure in each zone of conveyor can be regulated with a manual damper located at each blower. This will control the speed range of the section, and allow each zone to be treated separately if required. A gauge at each zone allows for pressure to be set at appropriate levels.

A handwheel adjustable pick-up section at the infeed/outlet section allows the air conveyor to pick up bottles of varying heights from tabletop or mattop conveyors and minimizes production changeover time.

Available

Bevco is a leading Air / Pneumatic Conveyor Manufacturer in Canada.

- Modular construction allows for control of individual zones

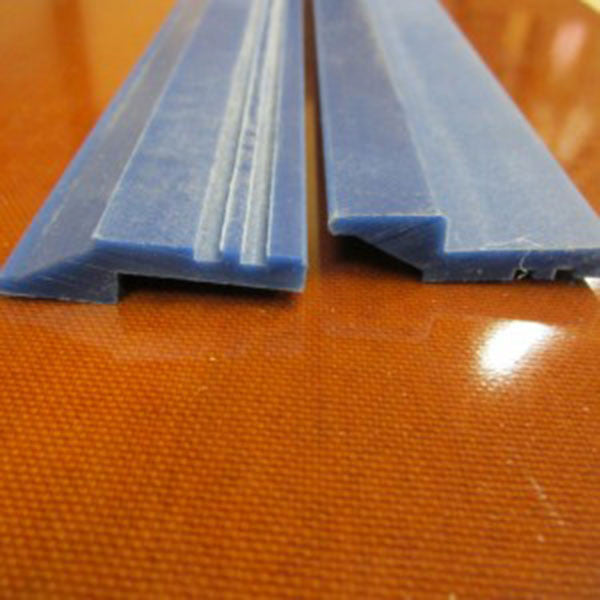

- Easy maintenance and quick changeover designs: clip-on neck guides, handwheel adjustable pick-up section, quick adjustable body guide rails, etc.

- Can be floor mounted or ceiling hung

- Custom height to suit customer requirements

Base Frame

Upgrade ($): Hepa filter Blower New York 3hp Neck guide Clip-on neck guide with one neck size.

Upgrade ($): automatic adjustable neck guides with multiple neck sizes. Guiderails Sanitary guiderails

Upgrade ($): air operated guiderails for automatic adjustment

Add-Ons

- Full control system with VFD controls

No electronic manuals/downloads are available for this product yet, please call 1-800-663-0090 or 604-888-1455 to inquire about available manuals and documents.