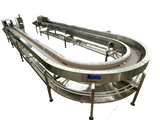

To solve these problems, Bevco designed the Horizontal Cap Sterilizer (ZPPI), which does not grip bottles by their sides; instead, it lays them down gently on a conveyor where they will ride for the required contact time.

Cap Sterilizer

Bevco's Cap Sterilizer (Horizontal – ZPPI, Vertical) is designed to tip hot-filled bottles on their side to allow hot liquid to sterilize the inside of the caps. At the entrance of the Horizontal Cap Sterilizer (ZPPI), the bottles are carried through a twist section, which gently lays the bottles on their sides without any squeeze pressure on the bottles, thus no resulting bottle distortion. The bottles are then carried for a distance on their sides to sterilize the caps and are returned to an upright position through a second twist.

Available

The Horizontal Cap Sterilizer (ZPPI) was initially developed to resolve a need in the juice industry to reduce costs involved in the process of hot-filled PET bottles. The standard gripper style cap sterilizer usually captures a bottle between 2 gripper chains and carry them vertically or invert them and carry them horizontally to allow hot juice to contact and sterilize the inside of the cap. As bottles become lighter to reduce the costs per bottle, the standard gripper style cap sterilizers were starting to distort the shape of hot bottles. The distorted bottles caused new problems such as increased product rejection rate, and increased line downtime due to problems feeding labelers with irregular containers. These problems increase production costs.

- No adjustment on the unit to change bottle sizes or shapes

- No bottle distortion

- Hot product remains at floor level, eliminating the possible safety hazard of dropped bottles

- Custom built (straight or curved units, incline or decline units)

Base Frame

| Material | Stainless steel, 11 gauge thickness, 304 grade, #4 finish |

|---|---|

| Cautionary Designs | Positive emergency discharge jam switch – stops machine when outfeed jams Downstream backup switch – stop machine when there is an unusual backup Emergency stop on machine infeed |

| Safety Designs | Stainless steel covers and guarding |

| Maintenance-friendly Design | Centralized internal bearing grease lines |

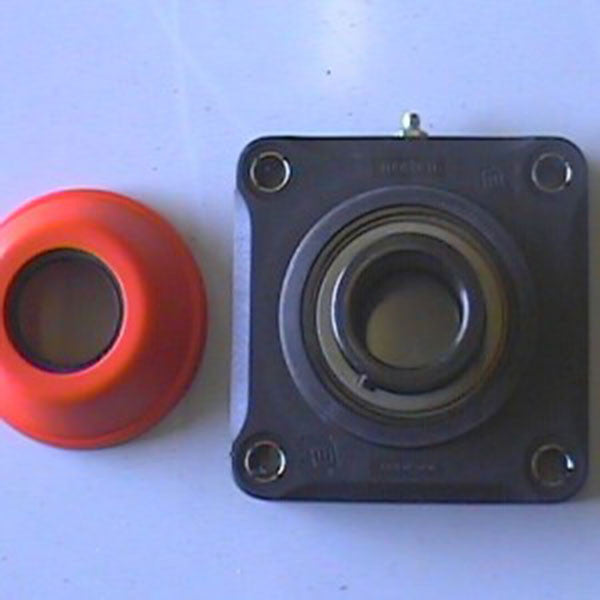

| Bearing | Polyamide bearings, eliminate rust problems |

| Chain | Stainless steel base chain with plastic flights and high friction inserts UHMW chain guides through twists |

| Drive | 3 phase motor |

| Controls | PLC controls with Allen Bradley Micrologix 1100 CSA/UL approved electrical control panel Touchscreen – Allen-Bradley PanelViewTM HMI C600 |

| Speed Control | Manual speed control Upgrade ($): automatic 2 speed controls Upgrade ($): direct pulse link to filler for automatic speed adjustments |