Rinsers

Bevco’s gripper-style Rinsers are able to rinse a wide variety of container types, including round, square, oval, tapered, and other bottle shapes, in many different materials (glass, PET, HDPE, aluminum). Over the last 40 years, Bevco has become renowned in the industry for supplying hundreds of high-quality, reliable Rinsers on packaging lines for many different foods and beverages, such as water, milk, juice, beer, cider, wine, kombucha, jam, etc. Our rinsers are designed to remove loose particulate or dust from bottles, and in some cases, can also be utilized as a part of a chemical sanitation system. For applications where there is a need to decline elevations from a high-level Depalletizer to a lower-level Filler, Bevco can manufacture custom-designed Lowerator Rinsers.

Bevco’s Rinsers are available in a variety of sizes to suit each individual application.

Available

Bevco Gripper Rinsers/ Air Rinsers are available in different models and lengths to fit all types of liquid and air rinsing applications.

- No change parts required on all Bevco Rinsers

- Minimal changeover/downtime.

- Accommodates different sizes of containers

Features:

- Bevco's own design of grippers supply a soft, gentle grip to prevent crushing for most standard containers

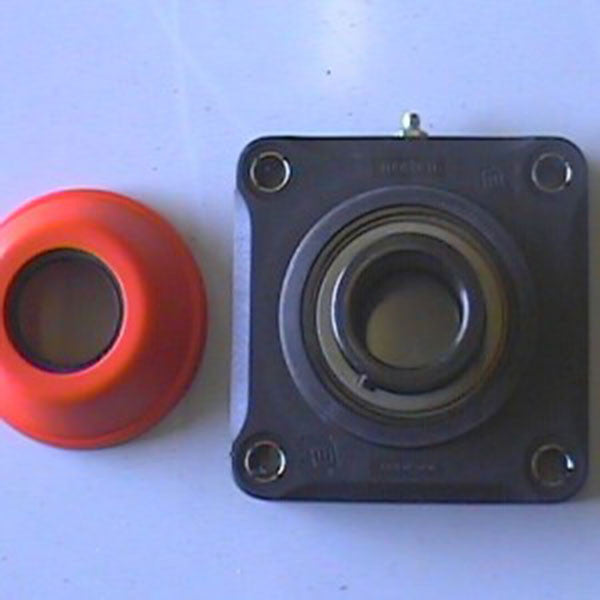

- Polyamide housed bearings eliminate the problem of rust (vs. regular bearings) for a wet environment

- Positive emergency discharge jam switch stops the machine before damage can be done if the outfeed jams

- Pressure switch will automatically stop the unit if the rinse medium is not present

- Standard water-saving shutoff when bottles are not present but the line is still running

- PLC controls allow for easy adjustments between products

- Variable frequency drive controls the speed

- Grease lines for bearings are run to a central header area with grease fittings labeled for easy maintenance

- Quick adjustment on spray header height. When bottle type/size is changed, nozzles can be repositioned for optimum rinsing

- All stainless steel construction

- SEW Eurodrives are standard

- CSA Approved electrical enclosures

- Handles container sizes from 1.5" to 9" in width and up to 13" in height

- Spray manifold and control solenoid capable of handling water, air or sanitizing solution with an optional multi-zoned manifold

Base Frame

| Material | Stainless steel, 11 gauge thickness, 304 grade, #4 finish |

|---|---|

| Cautionary Designs | Positive emergency discharge jam switch – stops the machine when outfeed jams Pressure switch – stop the machine when rinse medium is not present Water-saving shutoff – shut off nozzles when bottles are not present |

| Maintenance-friendly Design | Centralized internal bearing grease lines |

| Changeover-friendly Design | Quick adjustable spray header height |

| Gripper | Bevco D-style Gripper |

| Bearing | Polyamide bearings, eliminate rust problems |

| Drive | SEW Eurodrives |

| Electrical Enclosures | UL/CSA approved |

| Controls | PLC controls Variable frequency drive for speed controls Touchscreen – Allen-Bradley PanelViewTM HMI C600 |

| Speed Control | Manual Upgrade ($): automatic 2 speed controls Upgrade ($): direct pulse link to filler for automatic speed adjustments |

| Spray system | Standard one-zone manifold Upgrade ($): multi-zoned manifold Standard cast-steel painted regulator, brass solenoid valve, copper lube lines Upgrade ($): for corrosive chemical additives – plastic regulator, stainless steel solenoid valve, stainless steel lube lines Standard nozzles Upgrade ($): shockless ionized air nozzles with power supply |

Add-Ons

- Air filtration system

- Spray enclosure curtains

- Constant duty vacuum system

- Vacuum manifold for air rinser