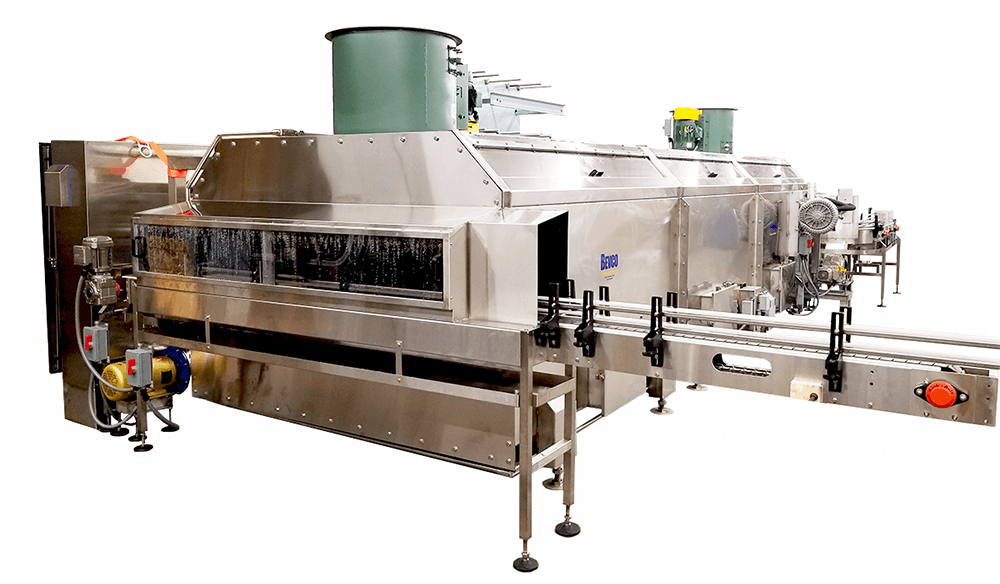

The primary cooling/warming source used is water, which is recirculated within each zone. No new water is added to the system unless the temperature of the water reservoir differs from the preset temperature threshold. The outfeed zone is the control zone of the machine; new water is added to this zone as required.

The Warming/Cooling Tunnel can be divided into various zones operating at different temperatures. For example, a Cooling Tunnel can be designed to cool only, or it can be configured to hold products at a high temperature first for pasteurization before cooling. In addition, glass bottles can pass through a series of gradual cooling zones to avoid thermal shock. Each section has hinged stainless steel doors through which machine operation can be observed and product removed.