Elevator/Lowerator

Bevco Elevators/Lowerators are designed to move containers from one elevation to another at line speeds. They are often used for palletizing and depalletizing product. They grip containers at the infeed elevation and raise or lower the containers, placing them on the outfeed conveyor. A single Bevco Elevator/Lowerator can be adjusted to accommodate various sizes and types of bottles, jars, cans, containers, and packages. A hand wheel provides one point adjustment of the spacing between grippers to accommodate varying container sizes.

Available

- Custom designed to meet your requirements

- No Change parts are required for various product types and sizes

- Single turning wheel for quick and easy changeovers

- Speeds up to 1200 containers per minute

- Accommodates round & non-round shaped containers up to 9” wide.

Base Frame

| Material | Stainless steel, 11 gauge thickness, 304 grade, #4 finish |

|---|---|

| Cautionary Designs | Positive emergency discharge jam switch – stops machine when outfeed jams |

| Safety Designs | Stainless steel covers at operators’ level |

| Maintenance-friendly Design | Centralized internal bearing grease lines |

| Conveyors | 2 feet infeed & discharge conveyors |

| Curves | UHMW curves Upgrade ($): anodized aluminum cast idler corner wheels for high speed/large elevation changes |

| Gripper | Bevco D-styled grippers |

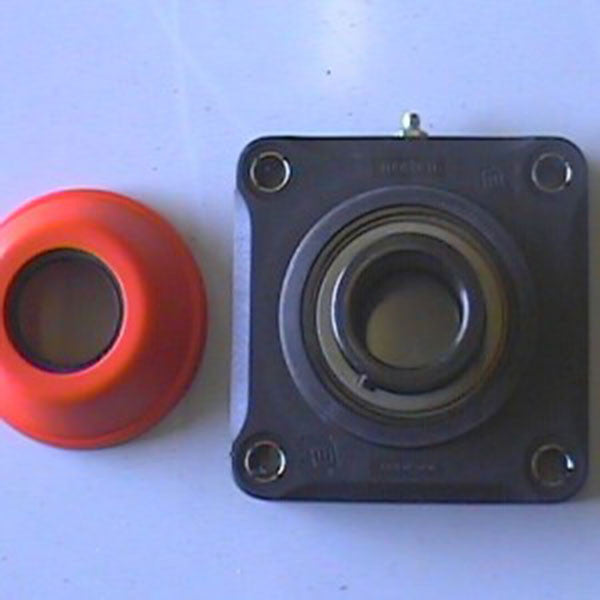

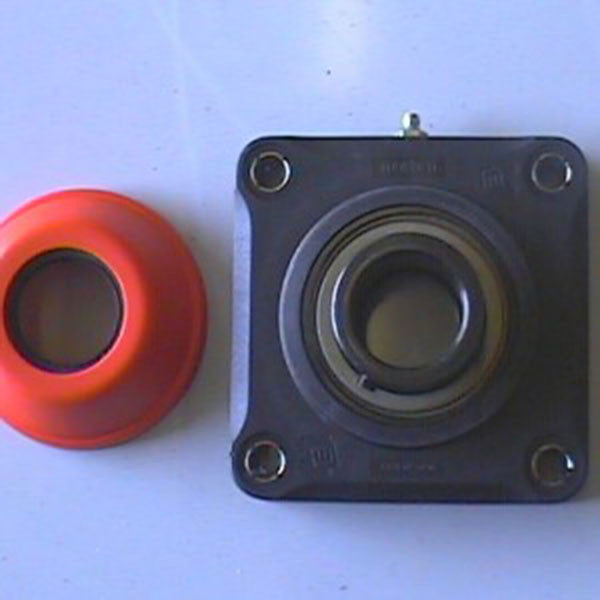

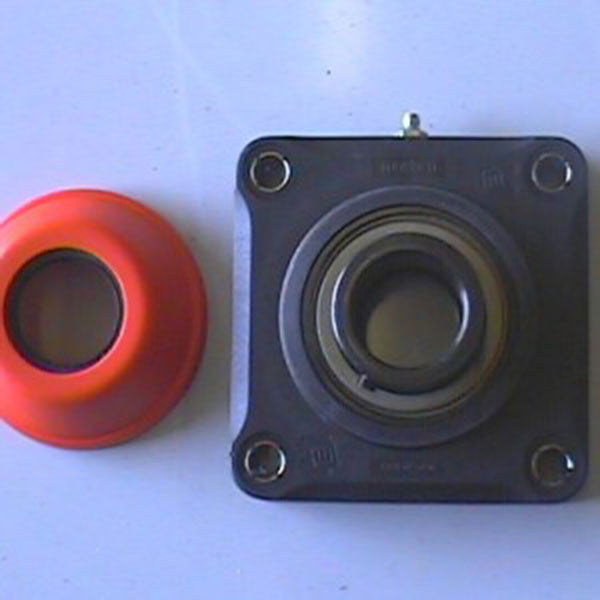

| Bearing | Polyamide bearings, eliminate rust problems |

| Controls | PLC controls with Allen-Bradley Micrologix 1100 Variable frequency speed controls Touchscreen - Allen-Bradley PanelViewTM HMI C600 |

| Speed Control | Manual speed control Upgrade ($): automatic 2 speed controls Upgrade ($): direct pulse link to filler for automatic speed adjustments |

No videos available at the moment.