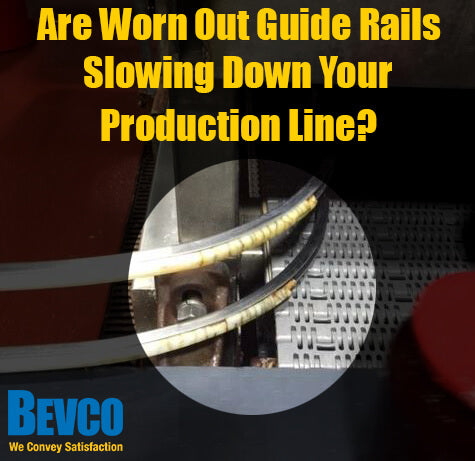

Are Worn Out Guide Rails Slowing Your Production Line?

All things wear out over time and guide rails are no exception. The chemicals in cleaning agents used on conveyors start to break down the plastic in guide rails over time. Additionally, the friction caused by bottles constantly rubbing against the guide rails can cause significant wear. Worn out guide rails lead to more downed bottles, bottled jams, and downtime for maintenance. Replacing the guide rails for the conveyor in your factory can provide a number of benefits to your production line from aesthetics to functionality to health and safety.

New guide rails can greatly improve the functionality of your packaging line leading to less downed bottles, less bottle jams, and less downtime for maintenance. Our staff will visit your factory and customize the guide rail layout to optimize bottle flow. This can result in higher operating speeds and smoother flow. Less clinking of bottles means less noise in the factory. We can also customize your new guide rails to adjust for various bottle sizes used in production. This will make changeovers for different bottle sizes easier and more efficient, reducing downtime.

New guide rails also create aesthetic value. Investors and customers touring a plant would rather see clean, even guide rails than worn-out ones in pieces and shambles. Your finished product will also benefit from improved guide rails as they create less friction on the bottle while it’s traveling through the bottling line, reducing wear and markings on the bottle and labels. There are now more options available than ever before for shapes and materials used for guide rails. If you have an older production line, there may be a type of guide rail better suited for your container than currently installed. With over 40 years of experience, it’s safe to say Bevco knows a thing or two about guide rails. If your bottle line is suffering from worn-out guide rails, contact us and we will be more than happy to help you get your bottle line back in tip-top shape.

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler

Related by Tags

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Thanks For Your Contribution To Flatten The Coronavirus Curve

- Custom Conveyor Solution: Applesauce Pouch Incline Conveyor

- Custom solutions that are tailored to suit your needs: Twist the plot with Bevco Twist Rinser

- Wet Cans or Bottles Causing Your Packaging Line Problems? Bevco’s Air Knife Tunnel Got You Covered!

- How To COPE with COVID-19 Outbreak For Breweries And Distilleries

- Bevco’s Innovative Hot-Fill Line Solution for Cap Sterilization and Cooling Challenges

- Hand Pack Off Table for Craft Brewery: Bevco’s Custom, Cost-Effective and Ergonomic Solution!

- Canning and Bottling for Craft Brewing: Variety Packs

- Keep Dust out of Your Cans and Bottles

- Bevco Container and Product Stackers

- Modular Conveyors Provide Adapabilty in the Bottling Line

- BEVCO: Continuing to Modernize and Automate our Manufacturing Process to Ensure our Competitive Edge.

- Are Worn Out Guide Rails Slowing Your Production Line?

- Keep the Filler Going!