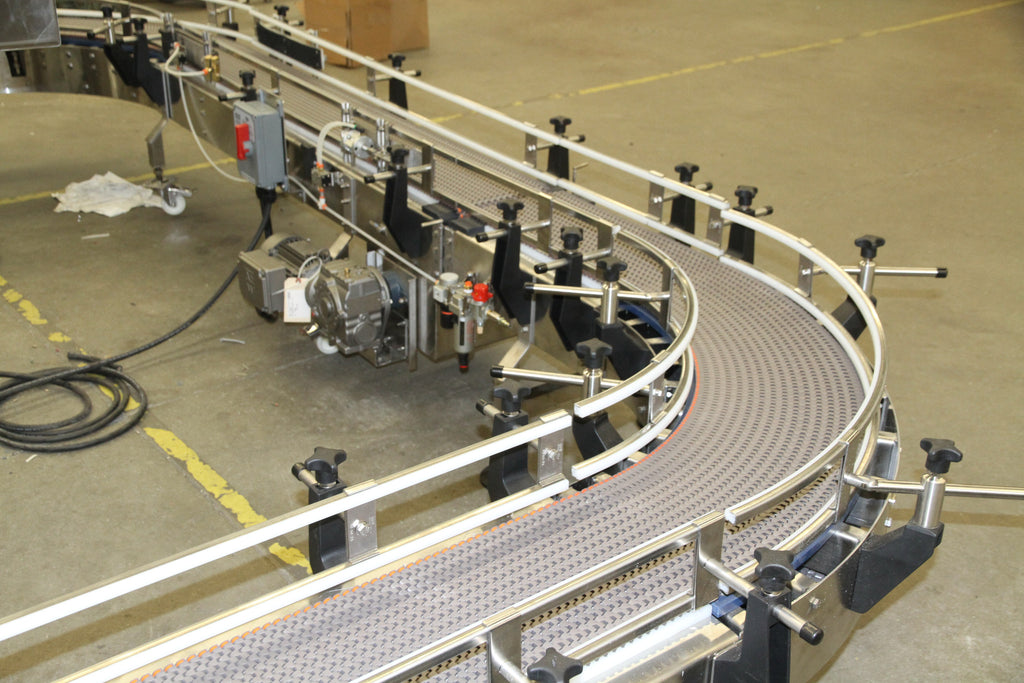

Modular Conveyors Provide Adapabilty in the Bottling Line

As companies in the bottling industry grow and expand, purchase new equipment, accommodate new products and make improvements in production, changes in the layout of the bottling line are inevitable. Modular conveyors make these changes easier and allow the customer to reuse existing conveyor. Bevco custom designs every conveyor system with modular components for easy interchangeability and adaptability of the customer’s bottling line.

The interchangeability of modular conveyor components makes adjusting the layout of the bottling line easy. Bevco’s conveyors are designed with matching inflow and outflows so sections can be moved around making augmentation and exclusion quick and easy (add or take away a section). This also makes installation easy; no welding is required, just bolts to fasten the sections together. Save money by re-using conveyor components in your new conveyor line, and when new conveyor is purchased, it easily connects with the old/existing Bevco conveyors. Modular conveyors come in short lengths and large sections are divided into smaller ones, making them lighter and easier to ship, install, or maneuver around the customer’s facility. Lastly, modular conveyors are easier to perform maintenance and repairs on as old or worn out parts can be swapped with new ones without disrupting the rest of the conveyor line. Integrating modular conveyor into your production facility will provide benefits for the lifetime of your bottling line.

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler

Related by Tags

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Thanks For Your Contribution To Flatten The Coronavirus Curve

- Wet Cans or Bottles Causing Your Packaging Line Problems? Bevco’s Air Knife Tunnel Got You Covered!

- How To COPE with COVID-19 Outbreak For Breweries And Distilleries

- Bevco’s Innovative Hot-Fill Line Solution for Cap Sterilization and Cooling Challenges

- Bevco's Custom Fabrication

- The Bevco Cooling Tunnel: A Cool Solution for a Hot-Filled Product

- Bevco Container and Product Stackers

- Modular Conveyors Provide Adapabilty in the Bottling Line

- BEVCO: Continuing to Modernize and Automate our Manufacturing Process to Ensure our Competitive Edge.

- Are Worn Out Guide Rails Slowing Your Production Line?