Hand Pack Off Table for Craft Brewery: Bevco’s Custom, Cost-Effective and Ergonomic Solution!

A common production task for producers of craft beer, kombucha, cider, soda, wine and other beverages, is packaging filled cans or bottles into trays, cartons, and other package types. Smaller beverage companies often do not have the capital to invest in automated packaging solutions and frequently rely on manual hand packing of containers into packages at the end of the packaging line. With over 40 years of experience working in the food and beverage industry, Bevco has manufactured a variety of end-of-line hand packaging solutions.

Local Craft Brewery Desires More Ergonomic Solution

Recently, a local craft brewery approached us with the desire to implement a more ergonomic hand pack off solution for packing beer cans into 24-can trays. Up until now, beer cans accumulated at the end of their single-file conveyor without any kind of pack off table or accumulation system, such as a rotary accumulation table. Based on the current equipment setup, workers have been dealing with sefveral ergonomic inefficiencies when transferring cans from the conveyor line into packages:

- There is limited space to grab the cans due to the positioning of the top guide rails at the tops of the cans. This results in stress on the workers’ fingers, hands and forearms.

- The high positioning of the guide rails relative to the can height also means that workers need to lift the cans out vertically from between the rails before bringing the cans back and down to the table. Lifting the cans up results in stress on the workers’ arms and back.

- The table that the cans are transferred to after removal from the conveyor is much lower than the conveyor height, causing workers to bend over and stand back up repeatedly.

Vision to Final Product

Bevco collaborated with this brewery to bring their vision for an alternate end-of-line hand packing solution to reality.

Benefits of the 24”x24” Hand Pack Off Table

The Hand Pack Off Table that Bevco manufactured has several benefits:

Custom Fabrication

- The majority of the projects we work on involve custom solutions that are tailored to suit our customers’ needs, and this project was no different. What started out as a customer vision and rough concept design, proceeded to a site visit meeting to review customer requirements in person, and then to the fabrication of the table itself.

Ergonomic Design

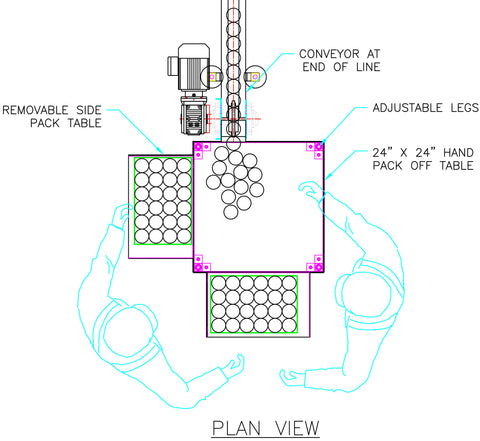

- The 3” tall side guides on the 24” x 24” table are high enough to restrain the cans and low enough to allow for easy access to grab the cans and pack them into trays on the side tables.

- The vertical distance between the top of the 24” x 24” table and the side tables is only 7 inches. This allows for more ergonomic transfer of cans from the upper table to the lower table without bending over.

- The square 24” x 24” shape allows users to stand at the corner of the table and reach all the way across to the other side. With pack tables on either side of the corner, two 24-can trays can be filled from one corner location by one worker.

Minimal Floor Space Requirements

- This table fits right at the end of the packaging line and is only 24” x 24” in size. The additional pack tables on the sides are only slightly larger than a 24-can tray.

Flexible Positioning of Side Pack Table

- The two side pack tables are easily adjustable side to side with ratchet handles bolted through slotted holes. This allows the workers to adjust the table positioning to suit their standing location.

- The two side pack tables are removable, and they can be positioned on 3 of the 4 sides.

Removable Side Guides

- The 3” tall side guides on the main pack table are fully removable, increasing user flexibility and customization.

Customizable 1.5" Square Tube Legs

- Adjustable foot pads

- Optional casters

Cost Effective Solution

- The small size and lack of moving parts results in a very cost-effective solution.

- Short Delivery Timeline

- After receipt of the order for this equipment, Bevco designed, fabricated and delivered this equipment to the customer within 2.5 weeks!

- Longer, narrow static pack tables positioned parallel to the conveyor

- Multi-chain accumulation conveyors

- Rotary accumulation tables

Do you have a vision on how you would like to do your beverage hand packing? We can work with you to turn your vision to reality! We can also help you assess your existing packaging line operations and help you identify an appropriate solution.

Please call (1.800.663.0090) or email (info@bevco.net) us today. We’d be happy to help you! Bevco…We Convey Satisfaction.

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler

Related by Tags

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Thanks For Your Contribution To Flatten The Coronavirus Curve

- Custom Conveyor Solution: Applesauce Pouch Incline Conveyor

- Custom solutions that are tailored to suit your needs: Twist the plot with Bevco Twist Rinser

- Wet Cans or Bottles Causing Your Packaging Line Problems? Bevco’s Air Knife Tunnel Got You Covered!

- How To COPE with COVID-19 Outbreak For Breweries And Distilleries

- Bevco’s Innovative Hot-Fill Line Solution for Cap Sterilization and Cooling Challenges

- Hand Pack Off Table for Craft Brewery: Bevco’s Custom, Cost-Effective and Ergonomic Solution!

- Bevco's Custom Fabrication

- Canning and Bottling for Craft Brewing: Variety Packs

- Keep Dust out of Your Cans and Bottles

- Who Likes Dirty Beer?

- Bevco Container and Product Stackers

- Are Worn Out Guide Rails Slowing Your Production Line?

- Keep the Filler Going!