Keep the Filler Going!

To achieve maximum productivity and profitability in a bottling line it is imperative to have continuous filler operation. To maximize production, one needs to produce the most amount of product for a given process in a given time frame. For example, if a plant is running at 100 bottles per minute (BPM) and the filler is stalled for 2 minutes each hour, there are 1600 less bottles filled at the end of an 8 hour shift. This translates to almost half a million less bottles produced in a year due to filler downtime.

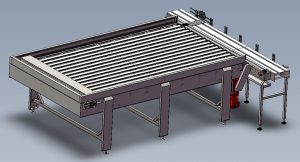

Water Bottle Filler

Two conditions can generally cause stoppage of the filler; starving the filler infeed and blocking the filler outfeed. Starving the filler is a result of insufficient supply of product from the infeed conveyor. Blockage of the outfeed occurs when downstream bottles back up in the conveyor line to the outfeed of the filler. This is usually caused by a stoppage in a downstream machine in the bottling line. These conditions can be eliminated by incorporating accumulators into the bottling line. Accumulators act as a buffer for the conveyor line by adding temporary storage spaces for products. When normal production flow is interrupted due to temporary product blockage, machine malfunctioning or adjustment, accumulators allow you to keep the filler going. For example, accumulation tables at the start of bottling lines are commonly used to avoid starving the bottling line during pallet changeover. Similarly, if a machine downstream of the filler gets jammed, an accumulation table will prevent bottles from backing up into the outflow conveyor of the filler. Bevco manufactures a variety of accumulation tables which are built to handle various types of containers. These include in-line accumulators, bi-directional accumulation tables, recirculating accumulation tables, and rotary accumulation tables. They can operate independently of existing equipment or be easily integrated into any line systems. Bevco can help customize your production line to optimize productivity and keep the filler going!

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler

Related by Tags

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Bevco’s Innovative Hot-Fill Line Solution for Cap Sterilization and Cooling Challenges

- Hand Pack Off Table for Craft Brewery: Bevco’s Custom, Cost-Effective and Ergonomic Solution!

- Canning and Bottling for Craft Brewing: Variety Packs

- Are Worn Out Guide Rails Slowing Your Production Line?

- Keep the Filler Going!