Canning and Bottling for Craft Brewing: Typical Can Line Layout

Brewing beer is the heart of the Craft Brewing Industry but canning and bottling beer plays a very important role in the production of craft beer. A label that is unique and stands out will draw customers to the product. A production facility that is properly designed and operates efficiently will maximize the output of products and profitability.

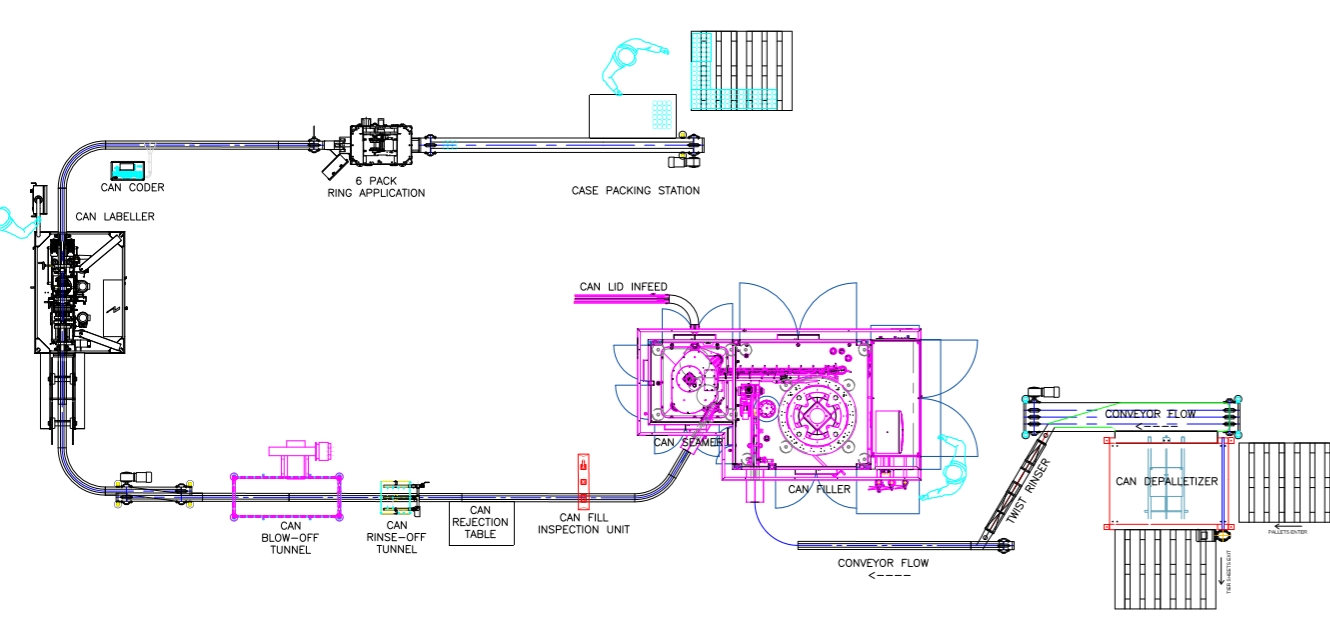

Each craft beer brewery has a unique brand and taste and their facilities vary in size, layout and beer producing capabilities. But one thing that stands common for most craft breweries is the design of their beer canning production lines. The order of machines that a can flows through may vary but most craft breweries will follow a layout similar to this:

- A depalletizer unloads empty beer cans from pallets onto a conveyor at an elevation higher than the rest of the beer canning line.

- The Cans are gravity fed through a twist rinser, which rotates the can upside down and rinses out the inside of the can, then rotates the can back onto its proper upright position at a lower elevation.

- A Filler pours beer into the empty cans.

- A Seamer applies lids to the full beer can.

- A can Inspection unit identifies cans that have been under-filled and kicks them off the canning conveyor.

- The Cans flow through a rinse-off tunnel to rinse beer overflow off their exteriors.

- The Cans flow through a blow-off tunnel to blow moisture droplets off their exteriors.

- A Sleever or labeller applies labels to the cans.

- A Can Coder prints a batch number or code onto the bottom of the cans.

- Plastic Rings are applied to tops of the cans in 6 pack or 4 pack formations.

- Cans are loaded into flats or boxes manually or using a case packing machine.

- Flats or cases of beer are loaded onto pallets manually or via a case palletizer.

Note that conveyors transport the beer can from each piece of machinery to the next and integrated electrical controls act as the brain of the canning line.

Bevco has a rich history building conveyors and equipment for canning lines since the 1980s. Check out our website for more information on products we manufacture for the craft brewing industry.

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler