BEVCO: Continuing to Modernize and Automate our Manufacturing Process to Ensure our Competitive Edge.

BEVCO is happy to announce that we have upgraded our lathe and brake press to improve the manufacturing process and product quality. The old brake press, built in 1985 required complete manual setups for bending by the sheetmetal worker. Our new brake press uses a cnc computer guided hydraulic bending system to shape the metal. This provides better accuracy for the bends, improving product quality. It also will make the bending process much quicker, allowing the sheet metal shop to turn out more product at a quicker pace. For projects that require multiple parts that are the same, the new press will make repetitive bends much easier and more efficient. Once the settings are input to the computer, the worker can quickly and efficiently make repetitive bends without needing to adjust settings or re-measure. This is a great improvement over the previous brake press system which required the worker to measure and mark the bend location on each individual piece of metal.

The new brake press is a robust piece of machinery which required a crane to lift it off the truck and move it into the building.

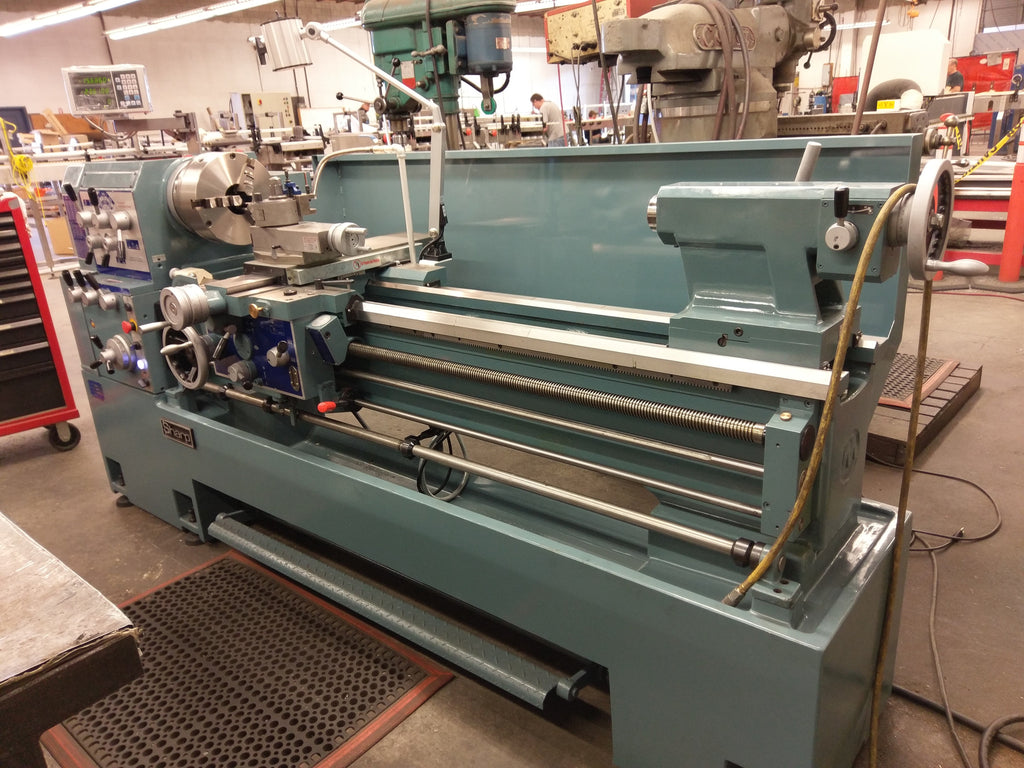

The new lathe will provide greater accuracy and precision in our machining department. It also has a greater capacity than the old lathe, giving Bevco millwrights more versatility and the ability to work on larger pieces of metal. The new lathe has a larger 3" bore with 60" centers compared to old lathe which had a 2" bore with 40" centers

.

BEVCO is continuing to modernize and automate our manufacturing process to ensure our competitive edge in the market.

In Same Category

- 45 Years of Bevco: Celebrating a Legacy of Quality, Innovation, Partnership, and Community

- Understanding the Essentials of Conveyor Systems

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Bevco's Hand Pack Off Table: The Perfect Pack Off Solution for a Wild Goose Gosling Filler

Related by Tags

- Enhancing Efficiency with Tool-Less Quick Changeover for Your Mix Pack System

- Why Your Packaging Line Needs a Variety Pack System

- Thanks For Your Contribution To Flatten The Coronavirus Curve

- Wet Cans or Bottles Causing Your Packaging Line Problems? Bevco’s Air Knife Tunnel Got You Covered!

- How To COPE with COVID-19 Outbreak For Breweries And Distilleries

- Bevco’s Innovative Hot-Fill Line Solution for Cap Sterilization and Cooling Challenges

- Bevco's Custom Fabrication

- The Bevco Cooling Tunnel: A Cool Solution for a Hot-Filled Product

- Bevco Container and Product Stackers

- Modular Conveyors Provide Adapabilty in the Bottling Line

- BEVCO: Continuing to Modernize and Automate our Manufacturing Process to Ensure our Competitive Edge.

- Are Worn Out Guide Rails Slowing Your Production Line?